This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Immunization is one of the most successful and cost-effective public health interventions in history, saving two to three million lives every year.

New vaccines such as pneumococcal conjugate vaccine and rotavirus vaccines could save many more lives. However, national immunization supply chains continue to face delivery challenges that result in poor temperature control, risks of reduced potency, and poor availability.

Functioning cold chain equipment is an essential part of the immunization supply chain. It helps maintain vaccines at the ideal temperature range to ensure vaccine safety and preserve potency.

In December 2017, JSI and Nexleaf partnered with the Tanzanian Immunization and Vaccination Development (IVD) of the Ministry of Health, Community Development, Gender, Elderly and Children (MOHCDGEC) and the President’s Office-Regional Administration and Local Government (PORALG) to install ColdTrace 5, a remote temperature monitoring (RTM) device, in 120 immunization sites, including the Mjimpya Dispensary.

CHRISTINA’S STORY

Inconsistent electricity in many health facilities can cause havoc with cold chain equipment. The equipment also needs regular, basic preventive maintenance to ensure its performance — a task which largely falls on health care workers.

Christina Ruvanda, a healthcare worker at Mjimpya Dispensary in the Morongoro Region of Tanzania, provides immunization and child services for up to 20 children per day and sometimes more.

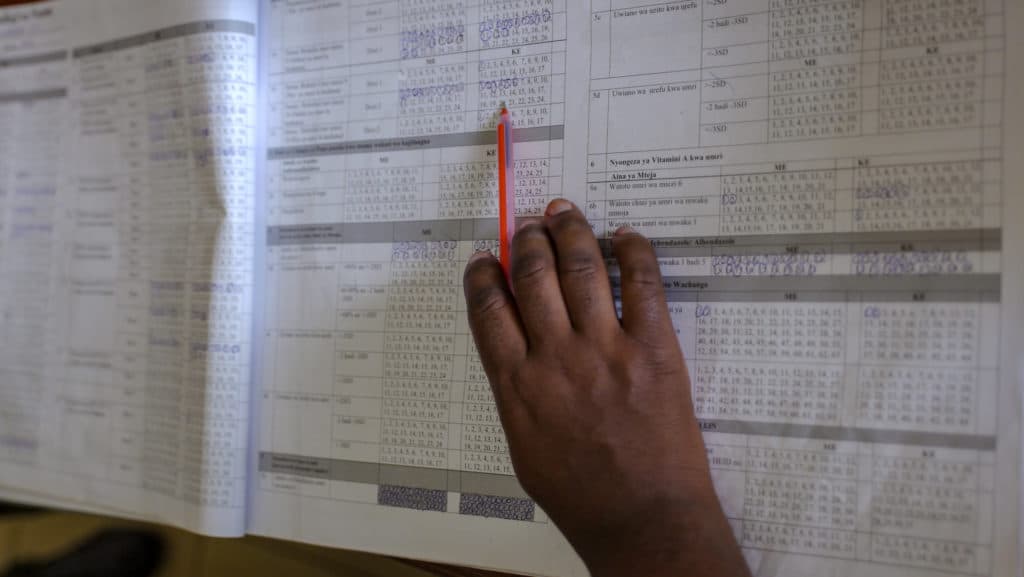

She maintains a child registry book to track each child and the immunizations they receive.

Christina is also responsible for monitoring the growth of the 380 children in the health facility’s catchment area.

In addition to seeing patients, Christina is also required to record the temperature of the cold chain equipment twice a day on temperature log charts, which provides little to no insight into what happens between temperature checks, after working hours, or over the weekend.

PREVENTING SPOILAGE AND REDUCING WASTE

The new RTM device sends data about the temperature of the cold chain equipment to a dashboard where it can be monitored remotely. The device also sends SMS alerts to health workers if the temperature falls outside of an acceptable range to help prevent vaccine spoilage and to reduce wastage. This device complements the existing IVD protocol for temperature tracking to provide more reliable data.

Since the ColdTrace 5 displays the temperature externally, Christina no longer has to open the fridge twice daily to check the thermometer. This improves the performance of the cold chain and reduces the strain of having to maintain the temperature through many opening and closings of the door.

The device also sends Christina a text message if the temperature goes out of the ideal range so she can immediately react, by either resolving the issue with the fridge or moving the vaccines to another refrigerator if the problem can’t be immediately addressed.

IMPROVING DATA VISIBILITY

From a dashboard, the Regional Immunization and Vaccine Officer (RIVO), Abdul Kakai can monitor the performance of cold chain equipment in health facilities in his region where an RTM device has been installed.

Abdul and his assistant, Joshua Edward, monitor the RTM dashboard to identify equipment that needs to be repaired or escalated to national level technicians for more corrective maintenance.

This data visibility allows Abdul to validate any concerns that Christina raises through her daily monitoring of the cold chain equipment in her facility.

REACHING THE LAST MILE

All of these activities ensure that vaccines make it to the last mile to prevent vaccine-preventable diseases, improve the health of vulnerable populations — and ultimately, save lives.